US Type

expansion joints

US Type

expansion joints

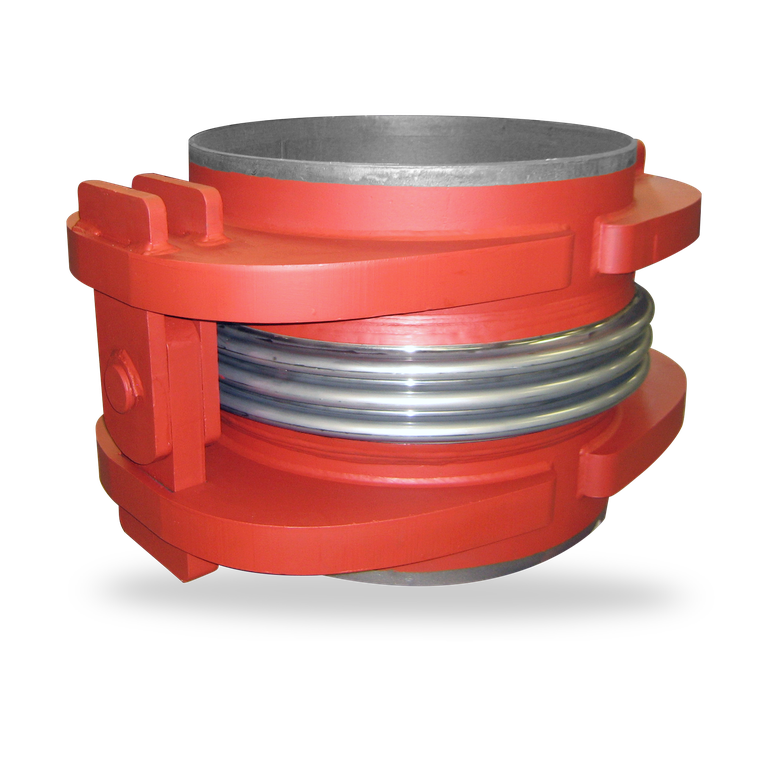

| Item | Description |

| 1 | Loose / swivel flange |

| 2 | Bellows |

| 3 | Internal liner (fixed) |

| 4 | Internal liner (loose) |

US Type

expansion joints

Features

- US type expansion joints are used in flue gas (exhaust) systems.

- For general applications with low pressure and high temperature.

- Designed for small vibrations and relatively large axial and lateral movements.

Advantages

- Highly customizable design: Bellows geometry, material options and combinations

- Multiply bellows with low spring rate and high cycle life

With loose / swivel flange connection:

- Easy installation, flanges can be rotated

- Flanges are not in contact with medium, which enables lower grade material

- Connection with non weldable materials possible

- Galvanic surfaces/ coatings possible

- Gaskets can often be eliminated

Materials

- Weld ends: 1.0038 - S235JRG2; 1.0425 - P265GH; 1.0254 - P235TR1; 1.0345 - P235GH; 1.5415 (16Mo3) ; 1.4404 (AISI 316L); 1.4436 (AISI 316)

- Bellows: 1.4541 (AISI 321); 1.4301 (AISI 304); 1.4306 (AISI 304L); 1.4401 (AISI 316); 1.4436 (AISI 316); 1.4404 (AISI 316L); 1.4435 (AISI 316L); 1.4571 (AISI 316Ti); 1.4828 (AISI 309)

- Flanges: 1.0038 - S235JRG2; 1.0425 - P265GH; 1.0315 - P235G2TH; 1.0254 (P235TR1); 1.0425 - P265GH; 1.5415 - 16Mo3; 1.4404 (AISI 316L); 1.4436 (AISI 316)

Other materials are available on request.

Standards and approvals

Design codes and options:

EJMA 9, EN 14917, EN 13480, EN13445-3, ASME B31.3

NDT and documentation:

Can be provided per customer request e.g. Material Certificates and NDT test reports.

EJMA 9, EN 14917, EN 13480, EN13445-3, ASME B31.3

NDT and documentation:

Can be provided per customer request e.g. Material Certificates and NDT test reports.

Recommended applications

- Petrochemical industry

- Chemical industry

- Power plant technology

- Shipbuilding

- Flue gas duct systems

- Engine exhaust systems

Product variants

US1: Single expansion joints

Expansion joints can be designed with one or two bellows depending on requirements for e.g., movements.

Expansion joints can be designed with one or two bellows depending on requirements for e.g., movements.

US2: Universal external joints

Expansion joints can be designed with one or two bellows depending on requirements for e.g., movements.

Expansion joints can be designed with one or two bellows depending on requirements for e.g., movements.

Similar products

AN Type expansion joints

- Tied custom metal expansion joints for general pressure applications.

- Designed for, and cover the mid temperature and pressure range for general process equipment.

- Mainly for angular movements.

- Tied metal expansion joints retain pressure thrust developed by internal pressure, through the use of hardware.

AX Type expansion joints

- Untied custom metal expansion joints for general pressure applications.

- Designed to cover the mid temperature and pressure range for general process equipment.

- Mainly intended for axial movements.

- Multiply bellows with low spring rate and high cycle life.

CB Clamshell metal expansion joints

- Bellows or expansion joints split into longitudinal segments for installation without opening pipework.

- Temporary repair solution for damaged expansion joints.

- Can handle axial, lateral and angular movements.

- The permissible combination and magnitude of movements depends on the application and the existing expansion joint that is to be repaired.